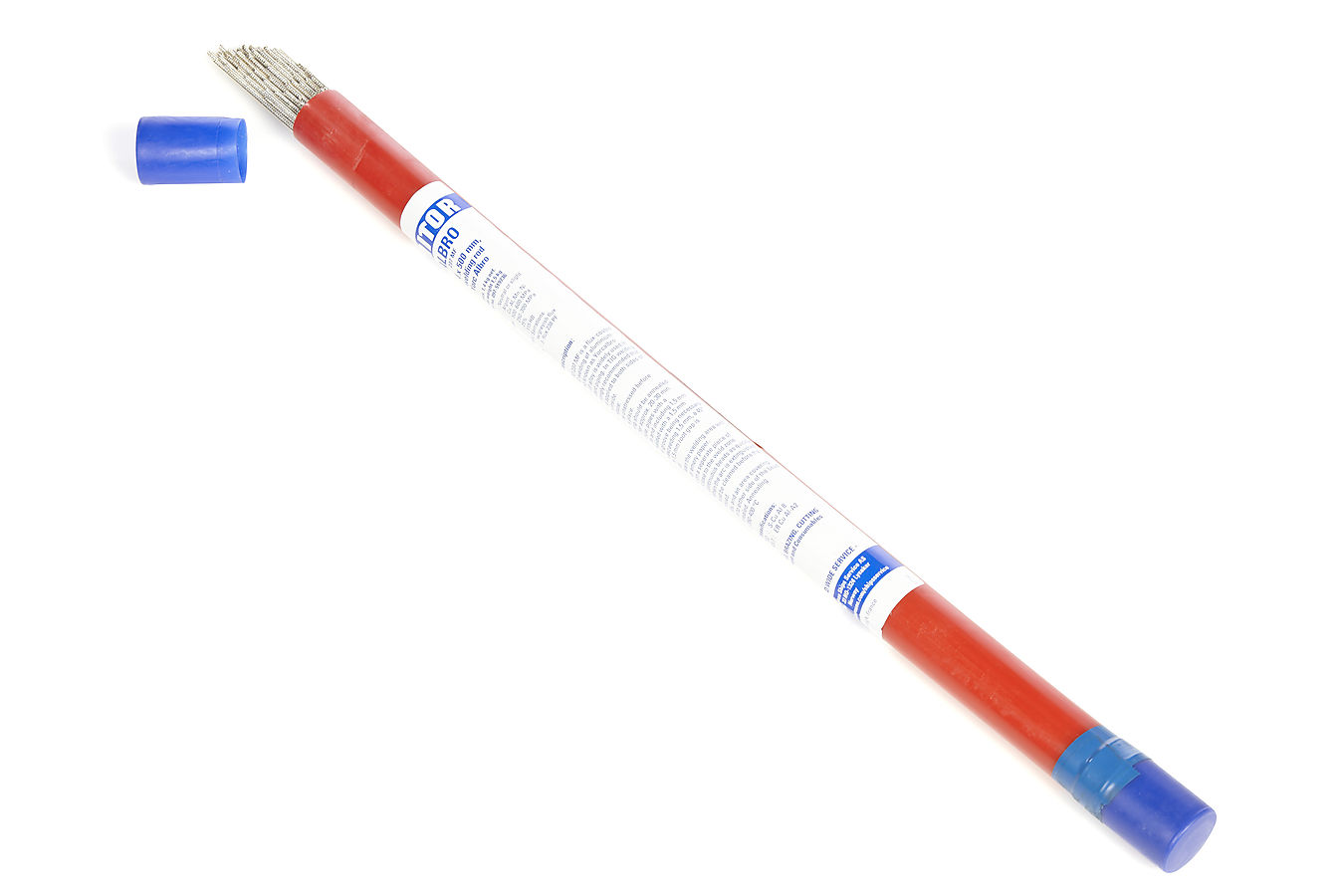

ICROMO-216 2.5 X 500 MM 1,0KG

Cr-Mo TIG welding rod for high temperature steel like boiler tubes.

Description

Chrome-molybdenum alloyed welding rod for TIG welding of heat resistant steels with working temperatures up to 550°C. Typical heat resistant steel types: 13 Cr Mo 44 — 22 Cr Mo 44.

Features

- Copper coated and high silicon content

- Can be used for thin as well as heavier sheets

- TIG welding should be preferred, but gas welding with acetylene/oxygen flame is possible

Benefits

- Rusting prevented during storing

- Fluid molten pool makes welding easy

- Welding of low alloy creep and hydrogen resistant Cr-Mo steels and also for high tensile steels, with weld deposit tensile strength > 560 N/mm2

Specification

General

| Invent Hazard Material (IMO/EU) classification | NA |

|---|

Dimensions/Weight

| Diameter [mm] | 2.5 |

|---|---|

| Length [mm] | 500 |

| Weight [kg] | 1.0 |

Technical data

| AWS | A5.28: ER80 SG* (*Nearest ER 80-B2) |

|---|---|

| Polarity | DC- |

Safety Data Sheet (SDS)

Documents

Directions for use

The label on each container fully identifies the contents, and also gives basic information on application areas. Complete information on each flux label, and instructions for use are given in the handbook for maritime welders.

- Use pure argon as shielding gas

- Weld with Leftward welding technique