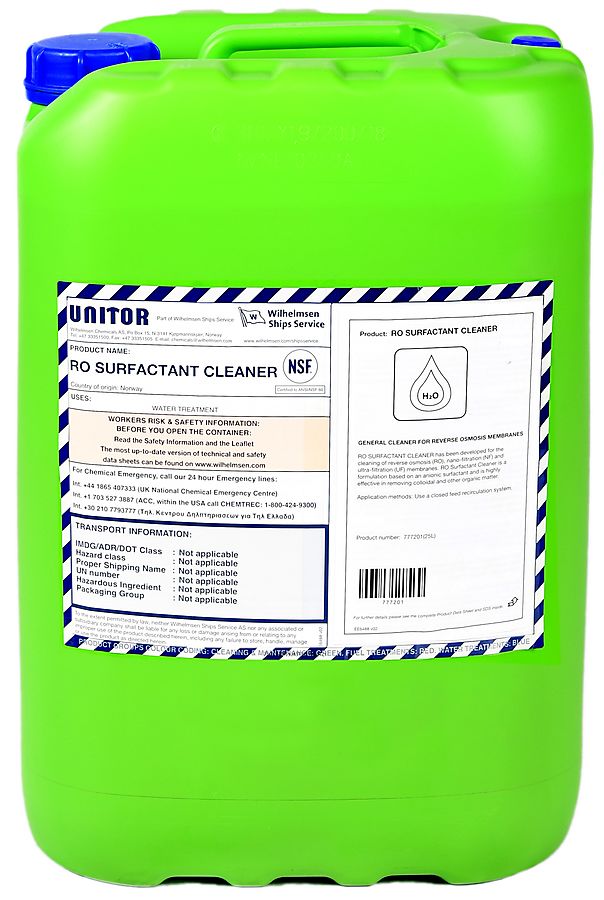

RO SURFACTANT CLEANER 25 LTR

NALFLEET™ RO Surfactant Cleaner™ has been developed for the cleaning of reverse osmosis (RO), nano-filtration (NF) and ultra-filtration (UF) membranes. NALFLEET™ RO Surfactant Cleaner™ is a formulation based on an anionic surfactant and is highly effective in removing colloidal and other organic matter.

Description

Product information

This product supersedes product no: PC-67.11R

Features

- Effective surfactant formulation

- Compatible with wide range of RO membranes

- Liquid formulation

Benefits

- Helps to maintain RO performance

- Effective dosage

- Certified by NSF in accordance with Standard 60 drinking water standards

Specification

General

| Invent Hazard Material (IMO/EU) classification | C-49 |

|---|

Physical properties

| Colour | Colorless to pale yellow |

|---|---|

| Density [g/ml] | 1.04 |

| Form | Liquid |

| Materials compatibility | All membrane elements based on Polyamide chemistries including Thin Film Composite (TFC) membranes when used as prescribed. 304 Stainless Steel Viton O-rings, Buna-N O-rings, Polyethylene piping, Polypropylene piping, HDPE, ULDPE, Epoxy phenolic. |

| pH | 7.0 to 9.0 |

Technical data

| Not Compatible | Coated steel phenolic , Neoprene O-rings, Hypalon O-rings , EPDM O-rings |

|---|

Note: Viscosity might increase during low temperatures. The recommended storage temperature is between 25-40 C.

Approvals

NSF International Certifies that this product conforms to the requirements of NSF/ANSI Standard 60 – Drinking Water Treatment Chemicals – Health Effects. For off-line use.

Safety Data Sheet (SDS)

Documents

Directions for use

During normal operation, RO membranes can become fouled, which greatly reduces the efficiency of the system. Deposits build up on the membrane until they cause a reduction in permeate flow and loss in salt rejection. The effects of fouling can lead to poor water quality, loss in production, unscheduled down time and membrane replacement. A regular maintenance and cleaning program can provide return on investment (ROI) results ranging from 100 to 250% by maintaining low pump output pressures and extending the membrane’s life.

Elements should be cleaned whenever the normalized permeate flow rate or salt rejection decreases by 10-15% or the differential pressure increases by 10-15% from the original baseline data.

NALFLEET™ RO Surfactant Cleaner conforms to the requirements of NSF/ANSI Standard 60 – Drinking Water Treatment Chemicals – Health Effects.

Dosing and Control

NALFLEET™ RO Surfactant Cleaner should be fed via a closed feed system. A closed feed system is defined as a system in which fluid is moved from a closed storage vessel into a treated media without exposure to the atmosphere except through normal venting or pressure relief devices. NALFLEET™ RO Surfactant Cleaner cleaning solutions are made at 1.0 – 2.0% (by weight) with chlorine-free product water and sodium hydroxide addition to give a pH of 10.5 – 11.0.